CAD/CAM Software

- Home

- CAD/CAM Software

CAD/CAM has been a boon for dentists since 1983. It created the first integrated CAD/CAM system in the market. Since then, significant advances have been made in workflow, design functions, and the level of detail that can capture. Despite these improvements, all dental labs remain divided into designers and fabricators. Architects use CAD/CAM programs to design plans. It is planned for construction without any concern about the details of designing or completing a structure. In this way, it acts as a digital blueprint for construction workers. It helps them to build according to master specifications without worrying about executing the specifications exactly.

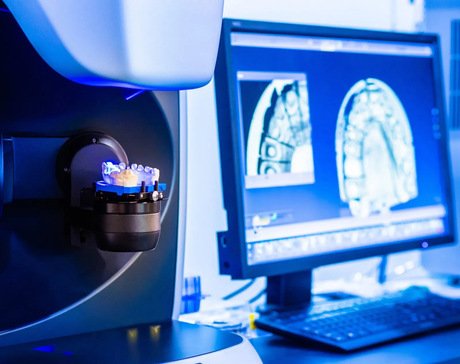

CAD/CAM (computer-aided design/computer-aided manufacturing) technology is quickly changing. We can see how dental lab technicians fabricate crowns, bridges, and other dental restorations. CAM systems assist technicians in formulating and fabricating ceramic restorations more precisely than ever before. Modern CAD/CAM systems are metal-free. It allows the dentists to safely use metal-free materials for custom milling of ceramics.

Dental laboratories use CAD/CAM to generate digital models of all kinds of teeth for crowns, bridges, and veneers. In addition, this technology is being used to produce better quality, cheaper dental prostheses.

CAD/CAM applications are used to design products and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software to generate toolpaths. It drives machine tools to turn designs into physical parts. The software is used to design and manufacture prototypes, finished parts, and production runs.

The new QuickCast system consists of an optical camera that takes a virtual impression. Then a software program converts the 3D image to a computer-generated cast on which the restoration is designed. Finally, a milling machine is used to mill out the restoration on which the crown is placed. This technology offers more precision in manufacturing, reducing manufacturing time while enhancing quality.

The CNC machining processes consist of multiple steps, all of which are performed by the CNC machine. First, the program to control the CNC machine is created using computer-aided design software. The CAD/CAM software then takes this data and converts it into the format to control the CNC machine. Finally, it controls the position, speed, and direction while being fed to enable the machining process. All of these steps, including design, simulation, and control, are automated by computer software.

With milling machines, the material is removed by rotating multi-pointed cutters. They are called mills against the workpiece. Milling machines are distinguished by the number of axes that they can control. Three-axis machining centers can operate in three directions (X, Y, and Z). Four-axis machines can run three tools simultaneously in the X, Y, and Z directions. At the same time, five-axis machines utilize additional rotary axes (U and V) to control spindles that can rotate or tilt in any direction. Each axis performs differently.

Using Turning, users can remove excess material, but oppositely. Instead of the cutting tool rotating, the workpiece itself is rotating to cut away the material.

CAD/CAM software will automate many different types of material removal processes. It includes milling and turning but also grinding, routing, and drilling.

With CAD/CAM software, you can also control additive processes, such as 3D printing. For example, the software can assist in manufacturing any shape by depositing layers of material on top of one another, forming an object.

The Fusion 360 set of 3D modeling tools connects the entire product lifecycle. Starting from ideation through manufacturing, as well as prototyping capabilities. This tool has it all, from a large set of 3D modeling tools to simple controls for programming your CNC machine. In addition, the tool is great for a team as there are ample data management features such as user permissions, version control, and cloud storage.

Solid Edge CAM provides the tools to create and edit machining strategies to maximize machining output. By taking advantage of five-axis milling, feature-based machining, and CNC simulation, this CAD/CAM system is adept at working with various manufacturing and engineering applications.

GibbsCAM is an industry-leading CAM package. It can assist you in keeping your machine time to a minimum and production quality to the highest level. GibbsCAM can speed up production and automate tedious tasks such as part modification and updating. The algorithms built into the system allow for complex workpieces. It's like complex three-dimensional shapes or parts with large tolerances. GibbsCAM offers four and five-axis machining and geometry tools. It is to create and revise shapes, creating complex profiles and simple 3D files. With this software, you can complete more than just one milling step without manually popping back into CAM.

Autodesk AutoCAD is a tool that allows designers and architects to work together more effectively. It reduces reworking time and sharing information. Its 2D and 3D functionality lends itself well to architecture, electrical engineering, mechanical design, and civil and general drafting. The software includes its drafting tools, textures, materials, and polylines.

At Roydentlabs, one can find the best CAD/CAM facilities and other dental laboratory products. We are here to build the best quality dental fixtures that help dentists solve their patient’s problems. It is cost-effective as well as takes less time in production. To know more about Roydentlab, log on to our website or reach us at 408 490 4292.